We provide a versatile range of steel grades based on JIS G 3311 Cold rolled special steel strip, including carbon steel, carbon tool steel, chrome steel, and chrome molybdenum steel.

We also provide steel grades other than those specified in JIS G 3311.

Types

| Classification | Steel grade | Chemical composition, % | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cu | Ni | Cr | Ni+Cr | Mo | ||

| Carbon steel | S20C | 0.18 - 0.23 | 0.15 - 0.35 | 0.30 - 0.60 | ≤0.030 | ≤0.035 | - | - | - | - | - |

| S35CM | 0.32 - 0.38 | 0.15 - 0.35 | 0.60 - 0.90 | ≤0.030 | ≤0.035 | ≤0.30 | ≤0.20 | ≤0.20 | ≤0.35 | - | |

| S40C | 0.37 - 0.43 | 0.15 - 0.35 | 0.60 - 0.90 | ≤0.030 | ≤0.035 | ≤0.30 | ≤0.20 | ≤0.20 | ≤0.35 | - | |

| S45CM | 0.42 - 0.48 | 0.15 - 0.35 | 0.60 - 0.90 | ≤0.030 | ≤0.035 | ≤0.30 | ≤0.20 | ≤0.20 | ≤0.35 | - | |

| S50CM | 0.47 - 0.53 | 0.15 - 0.35 | 0.60 - 0.90 | ≤0.030 | ≤0.035 | ≤0.30 | ≤0.20 | ≤0.20 | ≤0.35 | - | |

| S55CM | 0.52 - 0.58 | 0.15 - 0.35 | 0.60 - 0.90 | ≤0.030 | ≤0.035 | ≤0.30 | ≤0.20 | ≤0.20 | ≤0.35 | - | |

| S60CM | 0.55 - 0.65 | 0.15 - 0.35 | 0.60 - 0.90 | ≤0.030 | ≤0.035 | ≤0.30 | ≤0.20 | ≤0.20 | - | - | |

| S65CM | 0.60 - 0.70 | 0.15 - 0.35 | 0.60 - 0.90 | ≤0.030 | ≤0.035 | ≤0.30 | ≤0.20 | ≤0.20 | - | - | |

| Carbon tool steel | SK85M (Old SK5M) |

0.80 - 0.90 | 0.10 - 0.35 | 0.10 - 0.50 | ≤0.030 | ≤0.030 | ≤0.25 | ≤0.25 | ≤0.30 | - | - |

| Chrome steel | SCr420M | 0.18 - 0.23 | 0.15 - 0.35 | 0.60 - 0.90 | ≤0.030 | ≤0.030 | ≤0.30 | ≤0.25 | 0.90-1.20 | - | - |

| Chrome molybdenum steel | SCM415M | 0.13 - 0.18 | 0.15 - 0.35 | 0.60 - 0.90 | ≤0.030 | ≤0.030 | ≤0.30 | ≤0.25 | 0.90-1.20 | - | 0.15-0.25 |

| SCM420 | 0.18 - 0.23 | 0.15 - 0.35 | 0.60 - 0.90 | ≤0.030 | ≤0.030 | ≤0.30 | ≤0.25 | 0.90-1.20 | - | 0.15-0.25 | |

| SCM435M | 0.33 - 0.38 | 0.15 - 0.35 | 0.60 - 0.90 | ≤0.030 | ≤0.030 | ≤0.30 | ≤0.25 | 0.90-1.20 | - | 0.15-0.30 | |

| Steel grade | Chemical composition, % | |||

|---|---|---|---|---|

| C | Mn | P | S | |

| SAE1035 | 0.32 - 0.38 | 0.60 - 0.90 | ≤0.030 | ≤0.050 |

| SAE1042 | 0.40 - 0.47 | 0.60 - 0.90 | ≤0.030 | ≤0.050 |

| SAE1050 | 0.48 - 0.55 | 0.60 - 0.90 | ≤0.030 | ≤0.050 |

| SAE1055 | 0.50 - 0.60 | 0.60 - 0.90 | ≤0.030 | ≤0.050 |

| SAE1060 | 0.55 - 0.65 | 0.60 - 0.90 | ≤0.030 | ≤0.050 |

| SAE1065 | 0.60 - 0.70 | 0.60 - 0.90 | ≤0.030 | ≤0.050 |

Finish

| Type | Symbol | Remarks | Notes |

|---|---|---|---|

| Annealed | A | Annealed after cold rolling | We use bright finish for our materials. |

Skin-passed |

S | Cold rolled steel annealed and then tempered (skin-passed) | |

| As cold rolled | R | Cold rolled steel as is |

Hardness

| Type | Annealed A | Takasago special standard, Annealed A | As cold rolled R (for reference) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| JIS G 3311 | SAE equivalent | Takasago | HV | HRBS | HV | HRBS | HV | HRBS | (HRC) | |

| Carbon steel | - | 1020 | S20C | ≤150 | ≤78 | ≤140 | ≤75 | 190 - 230 | 90 - 97 | (9 - 18) |

| S35CM | 1035 | S35C | ≤170 | ≤85 | ≤150 | ≤78 | 200 - 240 | 91 - 98 | (11 - 20) | |

| - | 1042 | - | ≤170 | ≤85 | ≤160 | ≤82 | 200 - 240 | 91 - 98 | (11 - 20) | |

| S45CM | 1045 | S45C | ≤170 | ≤85 | ≤160 | ≤82 | 210 - 250 | 93 - 100 | (13 - 22) | |

| S50CM | 1050 | S50C | ≤180 | ≤88 | ≤160 | ≤82 | 230 - 270 | 97 - (102) | (18 - 26) | |

| S55CM | 1055 | S55C | ≤180 | ≤88 | ≤165 | ≤84 | 230 - 270 | 97 - (102) | (18 - 26) | |

| S60CM | 1060 | S60C | ≤190 | ≤90 | ≤170 | ≤85 | 230 - 270 | 97 - (102) | (18 - 26) | |

| S65CM | 1065 | S65C | ≤190 | ≤90 | ≤170 | ≤85 | 230 - 270 | 97 - (102) | (18 - 26) | |

| Carbon tool steel | SK85M |

- | SK85 SK5 |

≤200 | ≤92 | ≤180 | ≤88 | 240 - 280 | 98 - 104 | (20 - 27) |

| Chrome steel | SCr420M | - | SCr420 | ≤180 | ≤88 | ≤150 | ≤78 | 200 - 240 | 91 - 98 | (11 - 20) |

| Chrome molybdenum steel | SCM415M | - | SCM415 | ≤170 | ≤85 | ≤150 | ≤78 | 200 - 240 | 91 - 98 | (11 - 20) |

| - | - | SCM420 | ≤180 | ≤88 | ≤160 | ≤82 | 200 - 240 | 91 - 98 | (11 - 20) | |

| SCM435M | - | SCM435 | ≤190 | ≤90 | ≤170 | ≤85 | 230 - 270 | 97 - (102) | (18 - 26) | |

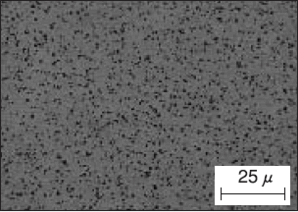

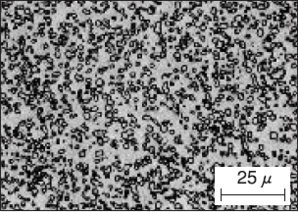

Structure

SCM415M spheroidizing annealing structure (x 400) |

SK85M spheroidizing annealing structure (x 400) |

Dimensional tolerances

(1) Thickness tolerances

| Thickness tolerances B | Thickness tolerances A | Takasago special standard | ||||||

|---|---|---|---|---|---|---|---|---|

| Width < 200 | Width ≥ 200 | Width < 200 | Width ≥ 200 | S standard | SS standard | U standard | ||

| 0.50≤ | <0.60 | ±0.035 | ±0.040 | ±0.025 | ±0.030 | ±0.020 | ±0.015 | ±0.011 |

| 0.60≤ | <0.90 | ±0.045 | ±0.050 | ±0.030 | ±0.040 | ±0.025 | ±0.020 | ±0.013 |

| 0.90≤ | <1.20 | ±0.055 | ±0.060 | ±0.040 | ±0.050 | ±0.030 | ±0.025 | ±0.016 |

| 1.20≤ | <1.60 | ±0.060 | ±0.070 | ±0.050 | ±0.060 | ±0.035 | ±0.030 | ±0.020 |

| 1.60≤ | <2.10 | ±0.075 | ±0.080 | ±0.055 | ±0.070 | ±0.040 | ±0.035 | ±0.025 |

| 2.10≤ | <3.00 | ±0.080 | ±0.090 | ±0.065 | ±0.080 | ±0.050 | ±0.040 | - |

| 3.00≤ | <4.00 | ±0.090 | ±0.100 | ±0.080 | ±0.090 | ±0.060 | ±0.050 | - |

| 4.00≤ | <5.00 | - | - | ±0.10 | ±0.11 | ±0.07 | ±0.06 | - |

| 5.00≤ | <6.00 | - | - | ±0.12 | ±0.13 | ±0.09 | ±0.07 | - |

| 6.00≤ | <7.00 | - | - | ±0.15 | ±0.17 | ±0.11 | ±0.09 | - |

Notes

1. The thickness of a steel strip is typically measured at a point within 10 mm of the edges. For pieces less than 30 mm in width, thickness is measured at the center.

2. To order sizes not listed above, please feel free to contact us.

3. Costs are higher for products made to meet special standards (SS and U).

(2) Width tolerances

| Thickness | Width < 200 | Width ≥ 200 | Notes | |

|---|---|---|---|---|

| 0.50≤ | <0.60 | ±0.15 | ±0.25 | JIS G 3311 |

| 0.60≤ | <1.20 | ±0.20 | ±0.30 | |

| 1.20≤ | <4.00 | ±0.25 | ±0.40 | |

| 4.00≤ | <5.00 | ±0.30 | ±0.50 | Takasago special standard |

| 5.00≤ | <6.00 | ±0.50 | ±0.65 | |

| 6.00≤ | <7.00 | ±0.60 | ±0.75 | |

(3) Length tolerances

| Thickness classification | JIS G 3311 0.5 - 4.0 |

Takasago special standard 4.0 to 8.0 |

||

|---|---|---|---|---|

| Width classification | Width < 200 | Width ≥ 200 | Width < 450 | |

| Length classification | 800≤ - <2000 | +5 | +10 | +10 |

| 0 | 0 | 0 | ||

| 2000≤ - <2800 | +10 | +20 | +20 | |

| 0 | 0 | 0 | ||

(4) Camber tolerances

| Width | Camber tolerance (mm/2 m) | Notes |

|---|---|---|

| 12≤ <21 | 32 | Takasago special standard |

| 21≤ <31 | 25 | |

| 31≤ <80 | 12 | |

| 80≤ | 4 | JIS G 3311 |

*Excluding SUY, SUYP

Available manufacturing range

Carbon steel, chrome steel, chrome molybdenum steel |

Carbon tool steel (SK85M, SK5M) |

| Coils Cut sheets The available manufacturing range will differ according to the steel grade, finish, size, dimensional tolerances, and mechanical properties. Contact us as for individual specifications.  |