We offer various steel grades to meet a range of workability requirements for cold rolled steel sheets and strips (JIS G 3141).

For applications that require increased strength, we provide the higher carbon TAK20.

Types

Cold rolled steel sheets and strips (JIS G 3141)

| Steel type symbol | Skin-pass symbol | Steel grade | Chemical composition, % | |||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | ||||

| General purpose |

SPCC | S | TAP8 | ≤0.10 | ≤0.08 | 0.20 - 0.50 | ≤0.035 | ≤0.035 |

| 8 | TAK8 | ≤0.08 | ≤0.08 | 0.20 - 0.40 | ≤0.025 | ≤0.030 | ||

| 4 | TAK10 | 0.08 - 0.12 | ≤0.10 | 0.30 - 0.60 | ≤0.030 | ≤0.035 | ||

| 2 | TAK12 | 0.10 - 0.14 | ≤0.10 | 0.30 - 0.60 | ≤0.030 | ≤0.035 | ||

| 1 | TAK20(*1) | 0.18 - 0.23 | ≤0.10 | 0.30 - 0.60 | ≤0.025 | ≤0.030 | ||

| Drawing | SPCD | S | TAP8 | ≤0.10 | ≤0.08 | 0.20 - 0.50 | ≤0.035 | ≤0.035 |

| TAK8 | ≤0.08 | ≤0.08 | 0.20 - 0.40 | ≤0.025 | ≤0.030 | |||

| Deep drawing |

SPCE | S | TAK8 | ≤0.08 | ≤0.08 | 0.20 - 0.40 | ≤0.025 | ≤0.030 |

(*1)TAK20 cannot be applied to the SPCC-SB type specified in JIS G 3141.

JIS G 3141 standard

| Steel type symbol | Chemical composition, % | |||

|---|---|---|---|---|

| C | Mn | P | S | |

| SPCC | ≤0.15 | ≤0.60 | ≤0.100 | ≤0.035 |

| SPCD | ≤0.10 | ≤0.50 | ≤0.040 | ≤0.035 |

| SPCE | ≤0.08 | ≤0.45 | ≤0.030 | ≤0.030 |

SAE standard

| Steel type symbol | Chemical composition, % | |||

|---|---|---|---|---|

| C | Mn | P | S | |

| SAE1008 | ≤0.10 | 0.30 - 0.50 | ≤0.030 | ≤0.05 |

| SAE1010 | 0.08 - 0.13 | 0.30 - 0.60 | ≤0.030 | ≤0.05 |

| SAE1012 | 0.10 - 0.15 | 0.30 - 0.60 | ≤0.030 | ≤0.05 |

| SAE1020 | 0.18 - 0.23 | 0.30 - 0.60 | ≤0.030 | ≤0.05 |

Finish

| Finishing category | Symbol | Remarks |

|---|---|---|

| Bright | B | Strips smooth-finished by smooth finished rolls |

Mechanical properties

(1) Tensile strength, elongation, hardness, and bending tests of skin-passed materials (S)

| Remarks | Steel type | Tensile strength, N/mm2 | Elongation, % | Hardness | Bending test | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Classification by nominal thickness, mm | Takasago special standard | |||||||||||

| 0.25≤ | 0.25≤ <0.30 |

0.30≤ <0.40 |

0.40≤ <0.60 |

0.60≤ <1.00 |

1.0≤ <1.6 |

1.6≤ <2.5 |

2.5≤ | HV | HRBS | |||

| General purpose |

SPCC-SB | - | - | - | - | - | - | - | - | ≤115 | ≤65 | Bend angle: 180° Inner radius: adhesion Test method: JIS No. 3 Rolling direction |

| SPCCT-SB | 270≤ | 26≤ | 29≤ | 32≤ | 34≤ | 35≤ | 36≤ | 37≤ | ≤115 | ≤65 | ||

| Drawing | SPCD-SB | 270≤ | 28≤ | 31≤ | 34≤ | 36≤ | 37≤ | 38≤ | 39≤ | ≤115 | ≤65 | |

| Deep drawing | SPCE-SB | 270≤ | 30≤ | 33≤ | 36≤ | 38≤ | 39≤ | 40≤ | 41≤ | ≤115 | ≤65 | |

*No. 5 test pieces are to be used for tensile testing.

(2) Hardness and bending tests of hardened materials

| Skin-pass classification |

Skin-pass symbol | Rockwell hardness | Vickers hardness | Bending test | ||

|---|---|---|---|---|---|---|

| HRBS | HV | Bending angle | Inner radius | Bending test piece | ||

| 1/8 hardness | 8 | 50 - 71 | 95 - 130 | 180° | Adhesion | JIS No. 3 test piece Rolling direction |

| 1/4 hardness | 4 | 65 - 80 | 115 - 150 | 180° | Half of thickness | |

| 1/2 hardness | 2 | 74 - 89 | 135 - 185 | 180° | Equal to thickness | |

| Full hard | 1 | 85≤ | 170≤ | - | - | |

*Normally, the bending test is omitted.

Dimensional tolerances

(1) Thickness tolerances

| Classification by nominal thickness | JIS G 3141 thickness tolerance B | Takasago special standard | ||||||

|---|---|---|---|---|---|---|---|---|

<160 |

160≤ <250 |

250≤ <400 |

400≤ <450 |

S standard | SS standard | U standard | ||

| 0.25≤ | <0.40 | ±0.025 | ±0.030 | ±0.035 | ±0.035 | ±0.015 | ±0.012 | ±0.010 |

| 0.40≤ | <0.60 | ±0.035 | ±0.040 | ±0.040 | ±0.040 | ±0.020 | ±0.016 | |

| 0.60≤ | <0.80 | ±0.040 | ±0.045 | ±0.045 | ±0.045 | ±0.023 | ±0.018 | ±0.012 |

| 0.80≤ | <1.00 | ±0.04 | ±0.05 | ±0.05 | ±0.05 | ±0.026 | ±0.020 | ±0.014 |

| 1.00≤ | <1.25 | ±0.05 | ±0.05 | ±0.05 | ±0.06 | ±0.030 | ±0.022 | ±0.016 |

| 1.25≤ | <1.60 | ±0.05 | ±0.06 | ±0.06 | ±0.06 | ±0.035 | ±0.025 | ±0.018 |

| 1.60≤ | <2.00 | ±0.06 | ±0.07 | ±0.08 | ±0.08 | ±0.040 | ±0.030 | ±0.020 |

| 2.00≤ | <2.50 | ±0.07 | ±0.08 | ±0.08 | ±0.09 | ±0.050 | ±0.035 | ±0.030 |

| 2.50≤ | <3.15 | ±0.08 | ±0.09 | ±0.09 | ±0.10 | ±0.060 | ±0.040 | - |

| 3.15≤ | <4.00 | ±0.09 | ±0.10 | ±0.10 | ±0.11 | ±0.070 | ±0.050 | - |

| 4.00≤ | <5.00 | ±0.10 | ±0.10 | ±0.11 | ±0.11 | ±0.08 | ±0.06 | - |

| 5.00≤ | <6.00 | ±0.12 | ±0.12 | ±0.13 | ±0.13 | ±0.09 | ±0.07 | - |

| 6.00≤ | ≤7.00 | ±0.15 | ±0.15 | ±0.17 | ±0.17 | ±0.10 | ±0.08 | - |

Notes

1. The thickness of a steel strip is typically measured at a point within 15 mm of the edges. For pieces less than 30 mm in width, thickness is measured at the center.

2. To order sizes not listed above, please feel free to contact us.

3. Costs are higher for products made to meet special standards (SS and U).

(2) Width tolerances

| Classification by nominal thickness | JIS G 3141 width tolerances C | ||||

|---|---|---|---|---|---|

| <160 | 160≤ <250 |

250≤ <400 |

400≤ <450 |

||

| <0.60 | ±0.15 | ±0.20 | ±0.25 | ±0.30 | |

| 0.60≤ | <1.00 | ±0.20 | ±0.25 | ±0.25 | ±0.30 |

| 1.00≤ | <1.60 | ±0.20 | ±0.30 | ±0.30 | ±0.40 |

| 1.60≤ | <2.50 | ±0.25 | ±0.35 | ±0.40 | ±0.50 |

| 2.50≤ | <4.00 | ±0.30 | ±0.40 | ±0.45 | ±0.50 |

| 4.00≤ | <5.00 | ±0.40 | ±0.50 | ±0.55 | ±0.65 |

| 5.00≤ | <6.00 | ±0.50 | ±0.60 | ±0.65 | ±0.80 |

| 6.00≤ | ≤7.00 | ±0.60 | ±0.70 | ±0.75 | ±0.80 |

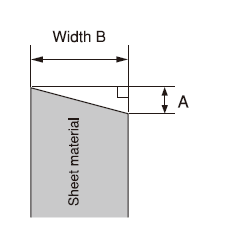

(3) Squareness

A/B ratio must be 1.0% or less.

(4) Length tolerances

| Classification by nominal thickness | JIS G 3141 length tolerances A |

|---|---|

| 800≤ - <2000 | +10 0 |

| 2000≤ - <2800 | +15 0 |

(5) Max. camber A

| Classification by nominal thickness | Steel sheet in lengths of less than 2,000 |

Steel sheet or strip in lengths of 2,000 or more |

Notes |

|---|---|---|---|

| 10≤ - <20 | 24 | 24 per any length of 2,000 | Takasago special standard |

| 20≤ - <30 | 16 | 16 per any length of 2,000 | |

| 30≤ - <40 | 8 | 8 per any length of 2,000 | JIS G 3141 |

| 40≤ - <450 | 4 | 4 per any length of 2,000 |

*Excluding SUY and SUYP

Available manufacturing range

|

Coils Cut sheets The available manufacturing range will differ according to the steel grade, finish, size, dimensional tolerances, and mechanical properties. Contact us as for individual specifications.  |